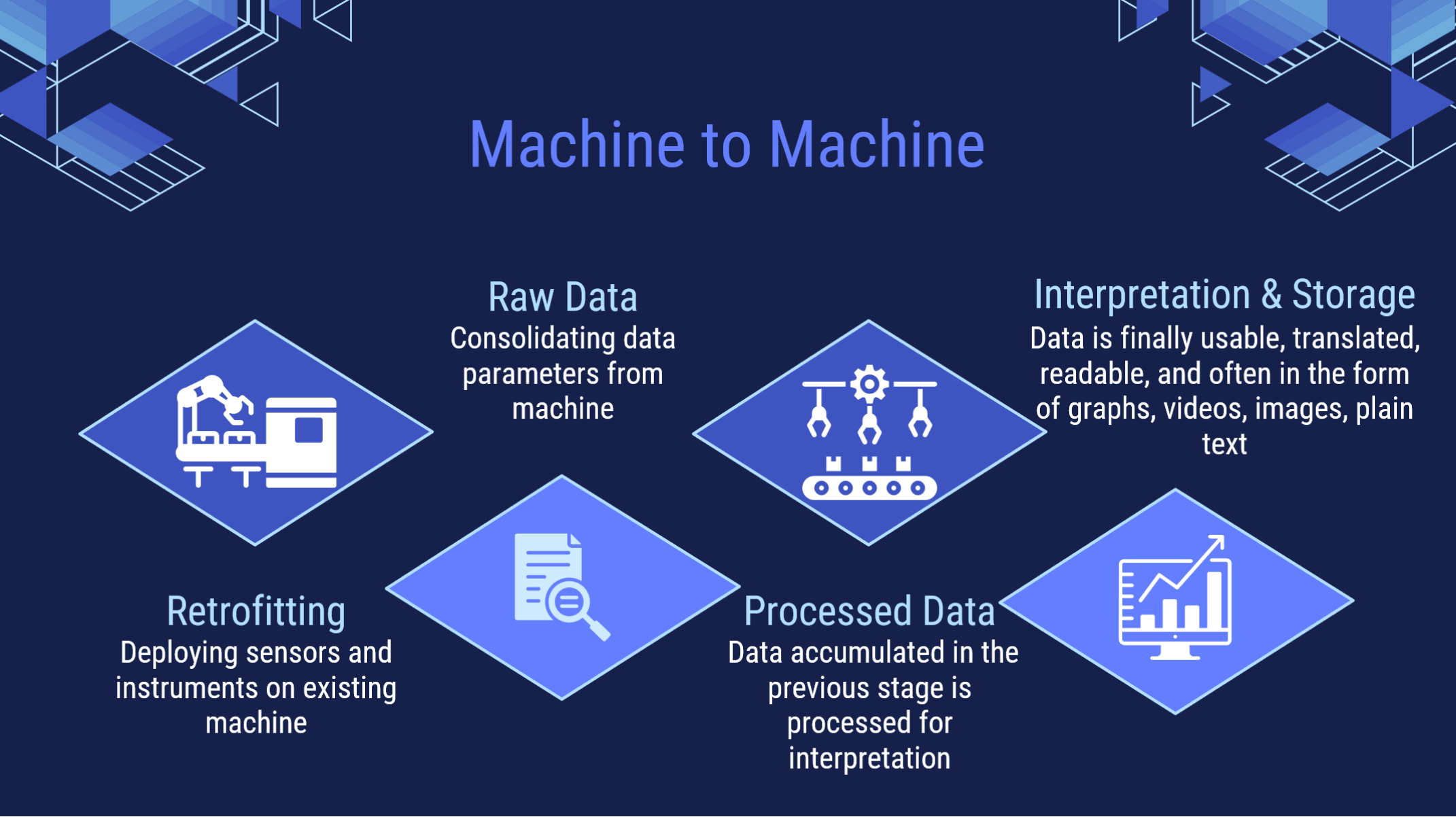

Machine Retrofiting

Adding Internet of Things (IoT) capabilities

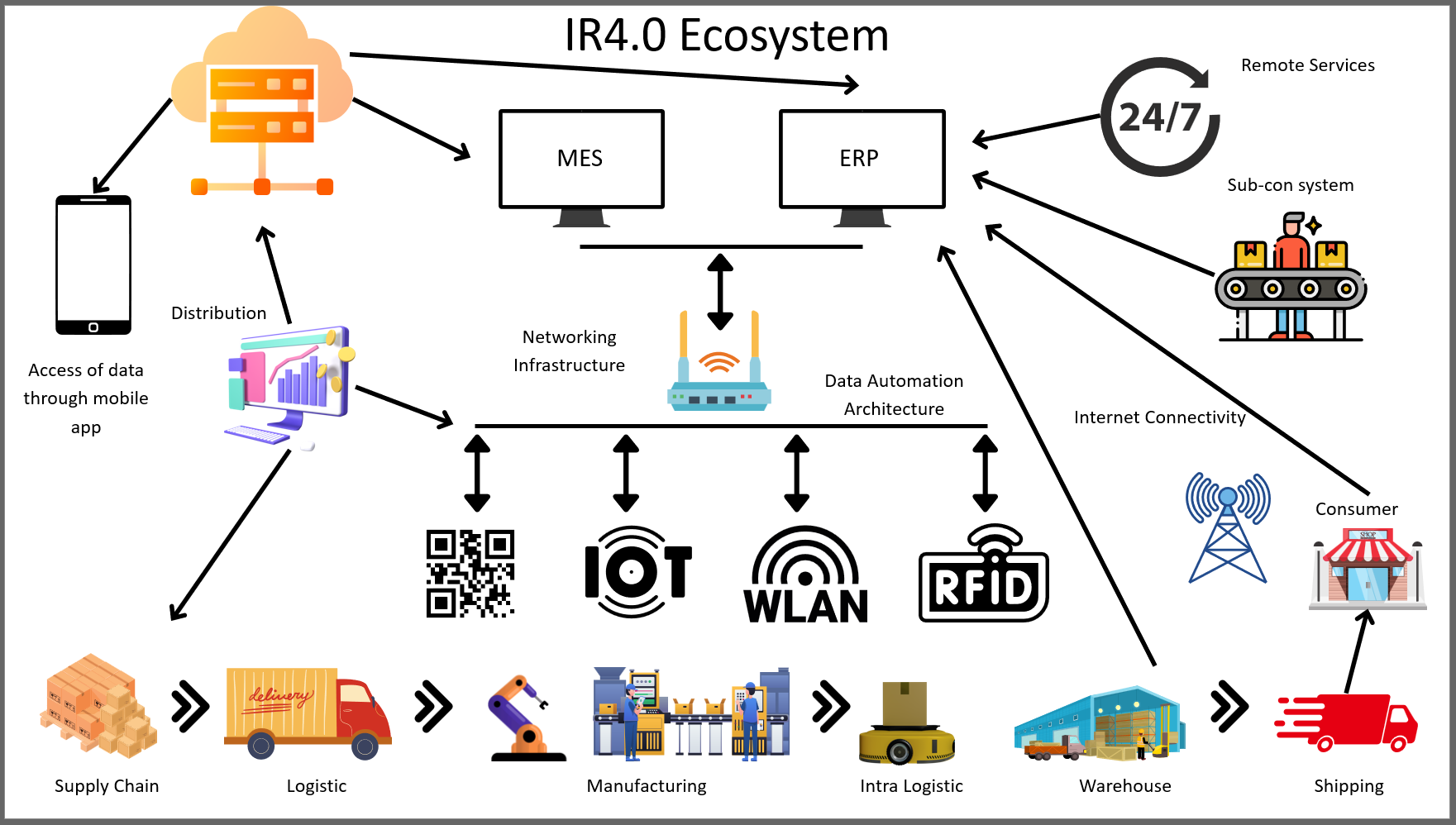

IoT devices can be deployed on the production floor to collect data from various sources, including machines, sensors, and even wearable devices. These devices communicate wirelessly and transmit data to a central system for analysis. IoT enables real-time monitoring, predictive maintenance, and data-driven decision-making.

By maintaining the current machine without modifying machine stock program

Component to get data from machine.

Performance of machine.

WLAN / WiFi

RFID (Radio Frequency Identification)

RFID (Radio Frequency Identification)

RFID tags can be attached to products, pallets, or containers to track their movement and collect data. RFID readers placed at specific points on the production floor can automatically capture information about the location, status, or quantity of tagged items. This method enables efficient tracking and traceability throughout the production process.

Internet of Things (IoT)

Internet of Things (IoT)

IoT devices can be deployed on the production floor to collect data from various sources, including machines, sensors, and even wearable devices. These devices communicate wirelessly and transmit data to a central system for analysis. IoT enables real-time monitoring, predictive maintenance, and data-driven decision-making.

Barcode Scanning

Barcode Scanning

Barcodes are commonly used to identify and track products, components, or materials. Barcode scanners can quickly read barcodes, capturing data such as part numbers, quantities, or serial numbers. The scanned information is then logged into a database or production management system. Barcode scanning is fast and accurate, making it suitable for high-volume environments.

- Physical Layer

Sensors on the Internet of Things (IoT) means that data can be tracked in every step of product creation, manufacturing, and delivery.

- Cloud

Through cloud computing, data can be stored, processed, and queried from almost anywhere.

- Devices

Smart gadgets allow managers to view this information from the factory floor from anywhere.

Indah Water Treatment Pond

Wastewater discharge monitoring is desirable for the following reasons: To assure responsible regulatory agencies of the manufacturers’ compliance with the effluent requirements and implementation schedule set forth in the discharge permit. To maintain sufficient control of in-plant operations to prevent violations of permit specifications To develop necessary data for the design and operation of wastewater treatment facilities.

Motor RPM Monitoring

The objective is to monitor RPM and protect if the induction motor parameters such as voltage, current, temperature and speed are exceeded above the normal value without using any sensor.

Robotic Palletizing

Low payload high volume

Proton Plant Material Handling System

Automated material handling system for Proton plant

Pharmaceutical System

Pharmaceutical system, pallet deduster for Biocon SILC

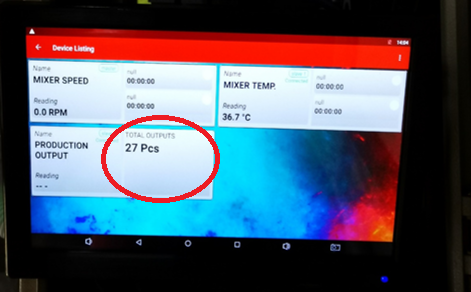

Output Count

IoT system uses sensors to count production throughput and provide real-time information about the actual output status to the production team

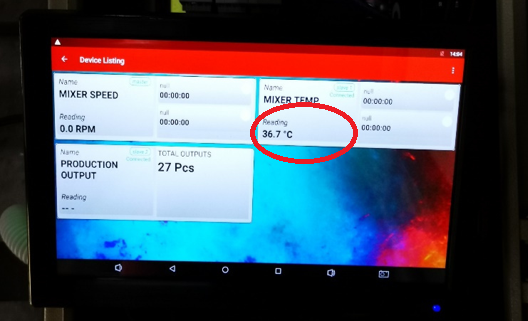

Monitor Machine Temperature

Measuring the temperature of the materials in the tank while it is mixing. Because the materials are easily affected by the air. IIoT system transmits the measuring data of the thermocouple to the cloud server

Silo Weighing System

Weighing process control implemented at material tanks

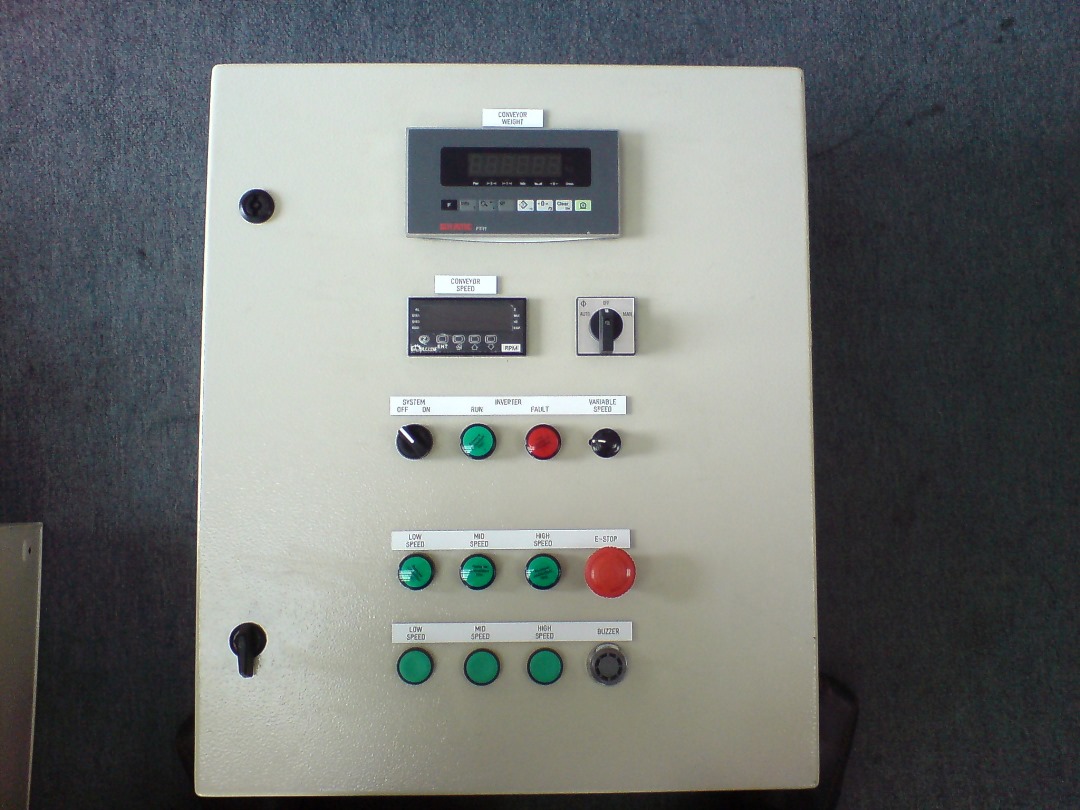

Weighing

weighing control panel for Tank weighing process control

Kindly contact us for more applications that you are interested in...